My name is Gloria Ni, and I’m a freshman SEED intern majoring in Bioengineering with interests in engineering design, global health, computer science, and applied mathematics. I’m passionate about healthcare equity and user-centered, sustainable design. Welcome back to my blog!

This week, our team collaborated effectively to brainstorm, evaluate, and visualize potential solutions in preparation for next week’s prototyping.

At the beginning of the week, we met with Treazar Jere, a registered nurse at QECH, and Wakisa Mwamwaya, a third year student studying Child health and pediatric nursing at QECH, regarding their training, expertise, and resources surrounding New Ballard Scoring (NBS). After hearing their input from a user perspective, we recognized the importance of the accuracy of the device’s physical appearance and revised our design criteria accordingly.

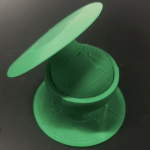

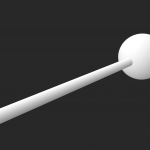

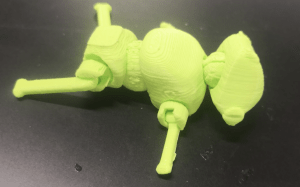

In order to visualize the mechanics of specific joints, we borrowed some articulated 3D prints from the OEDK and 3D-printed open-source files for a ball and socket joint and a humanoid robot with wheel and axle joints. Though the ball and socket joint provided a fluid range of motion, the thick handle prevented motion in some critical areas, so we designed a CAD model with a slimmer handle. Following some experimentation, however, we determined that a ball and socket mechanism may not be sufficiently durable, as the ball leaves the socket with strenuous force. From the 3D-printed robot, we discovered that a modified wheel and axle joint is a much more durable option that can further allow for full range of motion.

- OPEN-SOURCE BALL & SOCKET

- NIMBS BALL CAD

- NIMBS SOCKET CAD

WHEEL & AXLE ROBOT

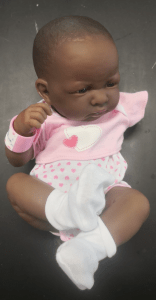

In addition, we purchased an adorable premature infant doll and performed an initial scaling, taking measurements of her extremities and joint diameters. Her name is NIMBS, of course, which stands for Nicki Iggy Madonna Beyonce Shakira. We named her after empowering female figures because she is a strong and high-impact device, and we hope that she will inspire confidence in nursing students (and we also just love honoring empowering women).

NICKI IGGY MADONNA BEYONCE SHAKIRA

Gathering our brainstormed solutions from last week regarding device structure and limb implementation, we utilized Pugh screening matrices to narrow down our list of solutions by scoring them against our design criteria. Our final solution was to create a model with a plastic torso base and silicon molding that covers a mechanical skeletal structure that exhibits the full range of motion possible of any neonate, without any resistance or flexibility that is specific to a certain gestational age. If time allows, we hope to implement adjustable resistances or interchangeable limbs after the initial design is completed.

During our weekly networking lunch, I spoke with Dr. Kristina Tebo, an Assistant Professor of Pediatrics at UT Health who had practiced inpatient and outpatient pediatric medicine at a rural hospital in Togo, West Africa. From her experiences performing the NBS in Togo, she provided valuable insight into the subjectivity of the assessment. This prompted our team to re-evaluate our solution, as a device with full range of motion fails to clearly distinguish the boundary positions for each score.

Moving forward next week, our team intends to begin low-fidelity prototyping for each joint, cast body parts to surround the skeletal structure, and hone CAD modeling skills.

I would like to conclude again with a huge thank you and acknowledgement to fellow NIMBS teammates, Lam Nguyen and Andrew Sun; our client, Prince Mtenthaonga; Assistant Professor of Pediatrics at UT Health, Dr. Kristina Tebo; QECH registered nurse, Treazar Jere; QECH nursing student, Wakisa Mwamwaya; our Design Supervisors, Shannon McGill and Alois Chipfurutse; and SEED/Rice 360 staff, Imari Fletcher, Dr. Deirdre Hunter, and Dr. Ashley Taylor. I’m very grateful that they made my experience these first couple weeks possible and extremely look forward to the upcoming week of prototyping!