This week I have probably spent a cumulative 20 hours staring at a computer screen. As I’m sitting here and typing the pixels are starting to blur together, so bear with me.

Our team ended last week by receiving our scissor lift and brainstorming any necessary modifications. Our plan is to keep the scissors as the main lifting mechanism, but add a hand crank to operate it. We will replace the top track of the lift with one made out of lighter material, and the chair will be collapsible and completely detachable from the lift.

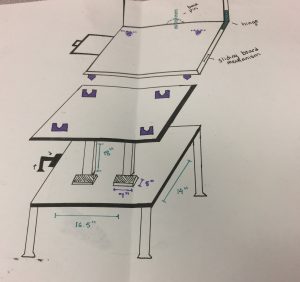

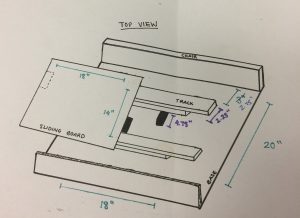

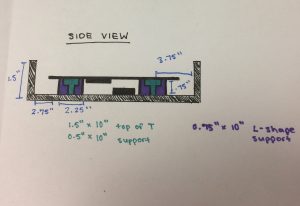

We spent the first part of this week creating our medium fidelity chair. We made detailed sketches of the chair and sliding board mechanism, clearly defining the size of each component. We also clarified every single connection for the device and incorporated it into our sketches. For example, we will be using hinges and pin connections to make the chair collapsible. However, we will be constructing a track for the sliding board out of laser cut wood and will bolt it to the base.

|

|

|

|

Dimensions for scissor lift, chair, and foot rests |

Details for sliding board mechanism |

Side perspective of sliding board mechanism |

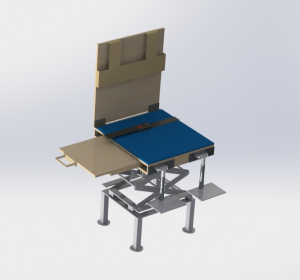

We then used these detailed sketches as a guide for creating a 3D model in Solidworks. Kalen and Jake both worked on the CAD model after spending a while working through Solidworks tutorials. For having learned the program in less than 48 hours, they did an amazing job.

|

| 3D model of device with moving components |

In addition to these drawings, we also made a physical prototype of the chair. We were able to attach it to the scissor lift and evaluate any modifications that need to be made in the high-fidelity chair prototype. One of the main insights we gained from this prototype was in terms of materials. We were able to see that a wooden chair would meet our design objectives, and would be more feasible to construct. Moving forward, we plan to make the entire chair from wood and add a vinyl seat cushion for user comfort.

|

| Chair made of cardboard with wooden sliding board chamber |

With a working chair prototype completed, we decided to research and order any materials not available at the OEDK for our high-fidelity prototype. After browsing the web for telescoping tubing and gears with no result, we asked for help from Dr. Wettergreen and Dr. Hunter. With their assistance, we were able to place an order for all our materials for the final device.

This upcoming week we will be starting our high-fidelity prototype as well as developing a testing plan. We have exactly 10 days until the final presentation, and only 12 more days until the end of SEED! With this finish line in sight, we will be sprinting this week to finish a successful device to deliver to our client.

Harrell and I enjoyed interacting with your team yesterday. We hope you can get the materials you need. Thanks to Jake for showing us the simulation.