Hello again! Week 2 of SEED is coming to a close and with it another jam packed week.

Through Monday and Tuesday we finished up the remnants of boot camp, including prototyping multiple iterations of our chosen device and presenting our final iteration to the rest of the program. As a recap, the problem we were tasked with was to create a puzzle feeder for the okapi at the Houston Zoo. Last Friday we chose to go forward with two devices, the first a puzzle feeder that enclosed multiple shelves that could be released, so food would drop down for the Okapi, and the second a hanging board that had different textured materials for the okapi to rub up against as well as holes for the zookeepers to place carrots in.

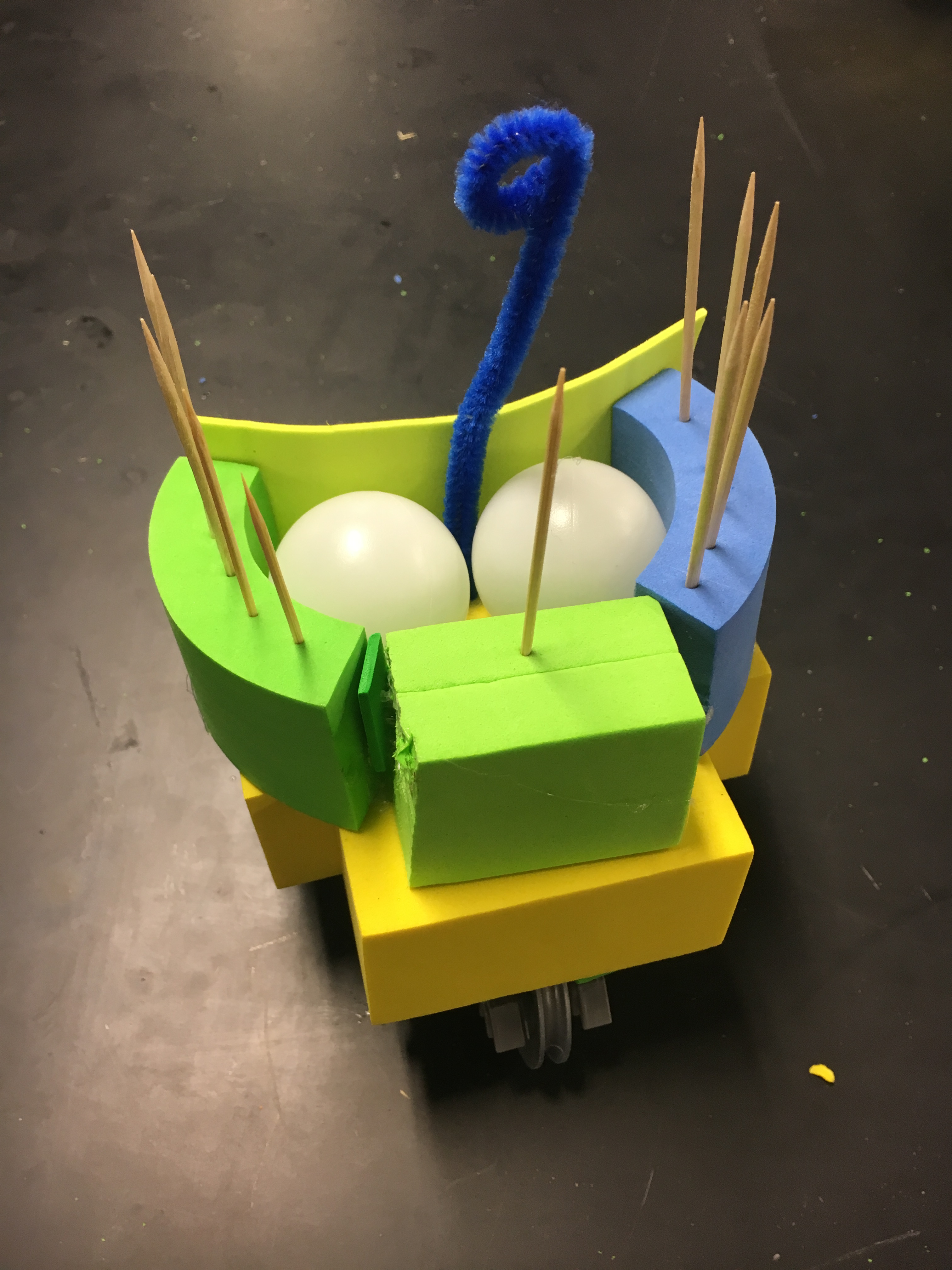

Going into Monday, we began by breaking apart into pairs to create a bajaj. This is a three wheeled device commonly used in India and other countries as a cheap taxi. After being given 30 minutes to create a device that could hold two ping pong balls while having an exposed top, we raced all of the bajajes against each other on a zip line to test whose could go fastest without knocking the ping pong balls out. My team did not have the fastest bajaj, but our first run was a success and the process of speed prototyping was a lot of fun!

We did some preliminary prototyping of each device early Monday, and decided as a team to continue on with the first option, the shelving puzzle feeder. My team began by each making a low fidelity (made out of cheap, easy to work with materials) prototype, and comparing what we came up with to find which version of the device we would choose to make with better materials.

After this, we discussed as a group and decided on our final design: a feeder with drop away shelving held up by a carrot! How it works is that the okapi will pull out the carrot from the device, which causes the food kept on the shelving to fall to the bottom, where the okapi will be able to eat it through holes in the device. From here, we were able to create a full scale version of this design out of cardboard, which successfully proved the concept we wanted to accomplish, and so we also made our final device (for now) out of laser cut wood. We were able to complete some preliminary testing later on Tuesday, and our final task of the day was to present our final design and the testing on it to the rest of the program! Although this was a very quick project, I really enjoyed being able to actually make a design and prototype it, something I haven’t been able to do since the school year.

Once we finished both boot camp and our Okapi device, we moved on to learning about the full time summer project options. The projects that we are working on this summer each have been worked on by a different team for at least one semester, and our job this summer is to finish these devices and to return them to our clients. Our TA, Jeremy, gave presentations over the four different devices, and after each intern ranking which team they would like to be on, we got our final assignments. I am very excited to say that I am now on Team Gotta Cast ’em All! Our project stems from the process of casting lower limbs to make personalized prosthetics for people. In the current process, the patient uses a set of parallel bars to hold themselves up while the doctor measures the limb in question and applies plaster to get a mold. This process takes around 10-15 minutes, however many of the patients who need this procedure are above 50 and have experienced muscle atrophy after recovering from an amputation. This leaves them weak and unable to comfortably hold themselves up while the casting is setting. This is where we come in. We were tasked with creating a casting stand that patients will use to hold themselves up with during the casting process that is both more comfortable for the patient to use and limits any restrictions to areas of the patient that the doctor needs access to.

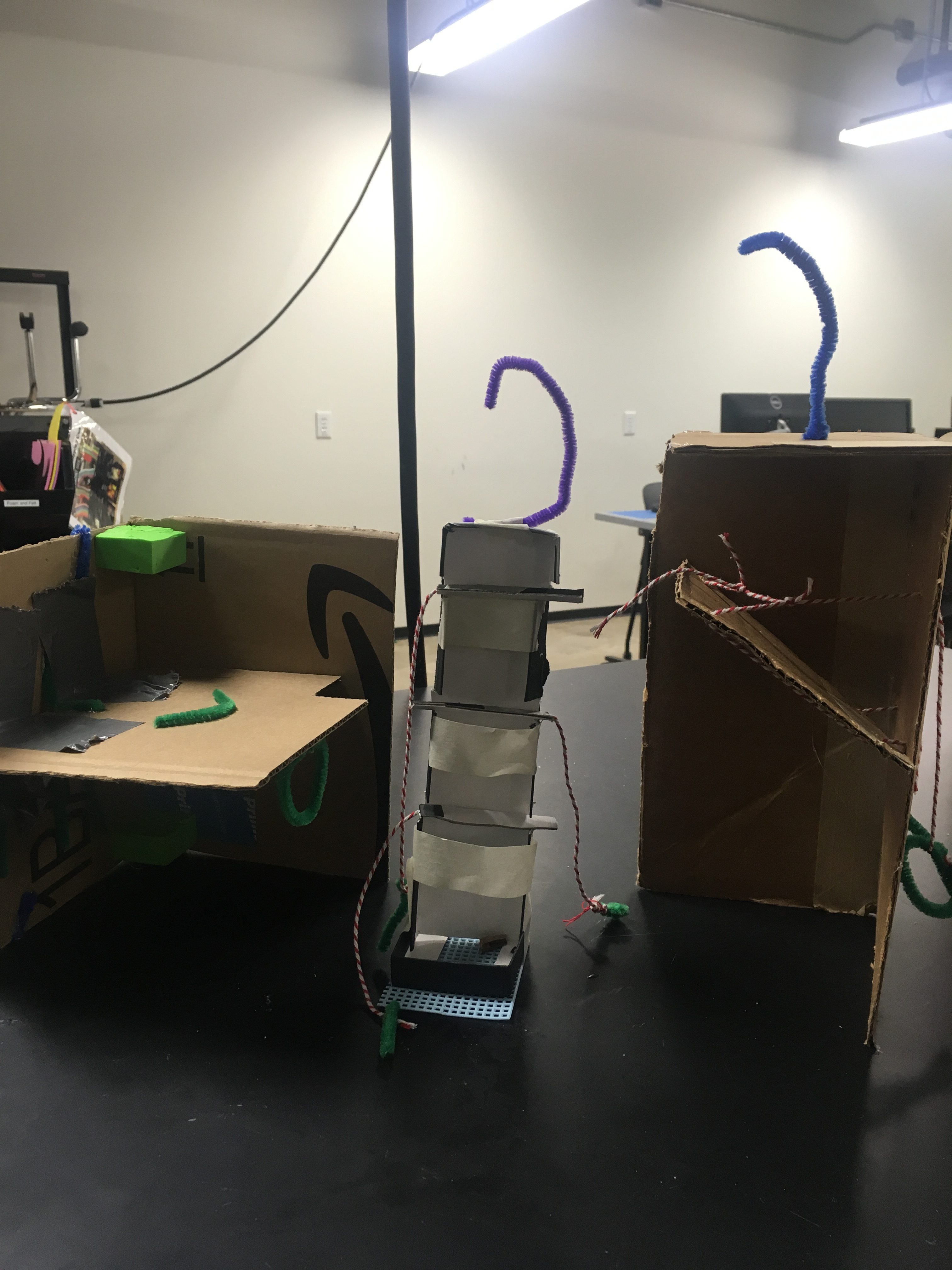

Through Wednesday and Thursday, our team began by looking over the documentation that the prior team left over the project and their though process leading them to the prototype they left with us. The device we currently have to work with does accomplish the design criteria (movable, adjustable, comfortable, etc.) however the execution is rudimentary, meaning we have a lot to improve on.

We closed out the week by attending a needs finding workshop led by a professor at Rice, who usually runs this workshop as a semester long course. The purpose of this was to show us where these ideas for projects come from: people experiencing needs. This class in ran through the bio-engineering department, so the focus was on medical needs. The most impactful part of the afternoon was when we experienced moving around blind, in a wheelchair, and eating as if we had arthrogryposis ( a disorder affecting the movement of joints). The process was both fun and difficult, and it really showed me how some of the things I take for granted can be so much more difficult for others, and that by putting myself in their shoes, I can more clearly see the needs that they have.

We are closing out this week by continuing to research on materials, attachment mechanisms, and similar devices, and finally we will be able to meet with our client this afternoon (Friday) which will clarify what our focuses and expectations will be this summer!

Until Next Week,

Liz Kacpura

I admire not only your engineering but also your superb verbal skills.