Despite the holiday on the 4th of July, this week has been pretty busy. We finalized a lot of design decisions and we developed a schedule for our prototyping process.

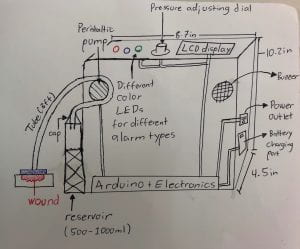

Since the previous team’s device achieved a range of successes, our selected design was not radically different. However, we did swap out one critical component: the pump. Instead of using a standard diaphragm pump, we decided we’re going to use a peristaltic pump. The peristaltic pump has a number of advantages over the diaphragm pump: it is silent, it creates pressure by compressing the tubing, and it consumes less power. This should lead to increase discreteness and a higher battery life. Furthermore, because the pressure is generated by compression of a tube, the need for a float-valve is eliminated: there is no risk of the waste fluid being drawn into the pump. This feature also means that there is no need to have air-tight seals on the cap, as there is no risk of air rushing in and eliminating the negative pressure.

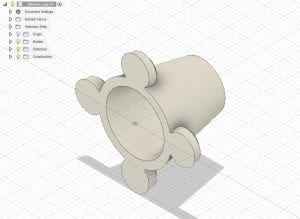

Although the pump and float valve changed, the rest of the design remained mostly unmodified: we liked the previous team’s chassis and universal cap so we kept those features. We also want to implement additional features. For example, we would like to add alarms that alert the user when the reservoir is full or when the pump is providing insufficient pressure.

After settling on this design, it was time to prepare our presentation for our peers and mentors. This required a significant amount of time as we wanted to be prepared and ensure that we had documented all the important areas of the process.

Having finished our presentations we decided to prepare our prototyping schedule. We decided our top priority would be to finalize the previous team’s prototype and identify all the problem sources. We would then build the CAD components for our cap, and begin assembling our circuit. Then, once we assemble the cap and debug our code, we would assemble all our components and test a medium fidelity prototype. We think this should take us into next week. After that, we can use another week to produce a high fidelity, more durable prototype and finalize with testing. There is still a way to go but we are happy with how we have manged to narrow down our scope to a specific design solution.

Your presentations by Alexander and Nneoma were well done. Your team appears to be well organized and making good progress. It is good that you are pleased with your progress, and I hope this feeling has put you in a place where you are enjoying some time off.

Your writing is consistently clear and well-organized, with well-chosen examples for clarification. I always look forward to reading your blogs.

Thanks! The weekend has been quite enjoyable and we are looking forward to what is coming up.

Enjoy!