Hello! Here to reflect on the fourth week of my time here as a SEED intern. This week will definitely go down as a highlight for the whole summer as it was filled with milestones for my team and I and fun activities for all the interns.

On Monday by listing the pros and cons of each of our highest scoring solutions we were able to finalize our decisions and pick a final design

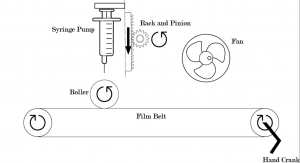

solution we can move forward with. Our two solutions, ro-loop and tracktion, were able to score the highest as they both utilized a roller applicator and a fan as a cooling method but differed in their mechanism as ro-loop had a belt loop and tracktion used a 6-ft track to hold the film stationary. Due to the difference in mechanism we were able to consider ro-loop as easier to implement for us as designers and our client and therefore went forth with it. After our decision, in order to give life to our design we all individually set out into our low fidelity prototype. Using

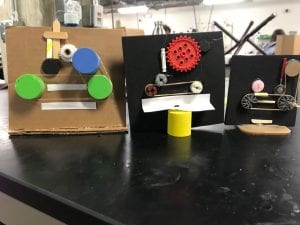

the raw materials available to us we were able to come up with a scaled

down version of what we all envisioned our device will become. We then shared our prototypes to each other so we can all get on the same page on what our device should encompass. Fortunately we didn’t differ so much as the only difference arose in how we wanted to incorporate our roller applicator: free to rotate or put in sync with the hand crank that powers all other moving components of our device. However, we saw this difference as a positive as it gave us two viable options for which we can test and incorporate our roller applicator, relying on the iterative nature of the Engineering Design process. The second half of Monday and the first half of Tuesday were then used to prep for our presentation on Tuesday afternoon. In our mid-semester presentation we were able to present on our progress and give an insight on why we chose and what our final design solution was.

After our presentation and for the rest of the week, we have dedicated our time into the

calculations needed to see that our mechanism actually works. We started with what seems to be our most important component of our

device, the gear systems that will translate rotary motion to linear motion. After multiple back-and-forth and guess and checks we were able to come to a number for the gear ratio for the bigger(slower) gear meshed with our rack and pinion and smaller(faster) gear connected our hand crank. We plan on grabbing cad models from an online gear shop and laser cutting our own to play with this ratio we found and see if it allows our mechanism to be functional.

One other big part that made the week fun was our little 4th of July shindig we successfully threw atop the college that our Brazilian friends stay at. We grilled for a little bit, ate, drank, ate some more and simply had a good time. I think we were able to share a little bit of ‘Merican culture with our friends and come together over some good ‘ol barbecue! I can’t wait to see what the rest of the summer has in store for us!

-Mathias