This week we calmed down, reviewed our work and improved our work with task division and it improved our results as well.

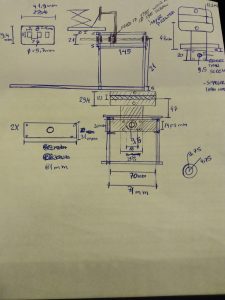

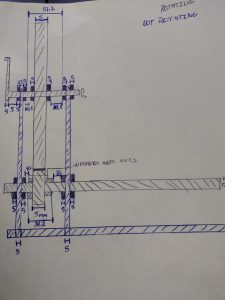

By the beginning of the week we changed our idea of the screw from a reverse thread to a gears Association and I started to project and prototype the gears, support, screw and thread. I defined the Force that the weight causes in the seat and in the base of the scissor lift, then I defined horizontal component of this force in the scissor and used the thread area of the screw to define the diameter of the screw. We have a 3.23 safety coefficient. After that I used the number of laps in the screw needed to move the scissor all the way up to define the size of the gears. Then I used the vertical force to define the torque that it causes in the screw, based on it and in the gear’s size I defined the lever’s beam length.

Based on it, and with the low-fidelity-prototype in hands, I did one draw (photo below) with all the parts needed to fix the screw in the scissor lift and with all dimensions, then I putted all it on Adobe Illustrator file. Now We will laser cut it and assemble our medium-fidelity prototype of the screw. After that we will order the materials needed to make our high-fidelity-prototype.

Screw Draw Screw Draw