In week 2, we continued and concluded our engineering design boot camp. After an eight-hour grind of screening and scoring our plethora of solutions for an enrichment device for the Baird’s Tapir. It was tedious and exhausting work, but once we completed it, we had our final solution!

Ever heard of the game Kerplunk? If not, you can see a picture of it below. It is a kids game where a pile of marbles is laying on a series of sticks, and the goal is to remove the sticks without the marbles falling down onto the ground. It was a very enriching game as a kid, so I thought an adaptation of the game could be a great way for the tapirs to be fed. Amazingly it was our selected solution. In this kerplunk-inspired solution, the frame of the game would look similar, but instead of the sticks, replace it with tree branches and browse, and instead of the marbles, replace it with the tapir’s food. The idea was that the tapirs would chew and pull the sticks, which would then cause the food to fall to the ground for them to eat.

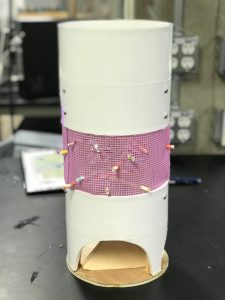

After we got this idea, we began prototyping. We first began low-fidelity prototypes so that each member could express what the solution could look like. After we came to a consensus, we began building the medium-fidelity prototype out of PVC and plastic mesh and wood. After a day of strenuous cutting, gluing, and sanding, we built a representational model of the final solution.

After testing the device, we revised our final solution plan so that the entire frame should be made out of PVC for durability while the mesh should be made out of either bamboo or plastic. It would also stand 3 feet tall and 1 foot wide instead of the prototyped 1.5 feet tall and 6.5 inches wide prototype.

We prepared and presented our hard work these five days, and the boot camp finally (or sadly?) came to an end. We were ready to begin our summer-long project.

I got assigned to the Reel Film project. We will be working on making an analog film-coating machine that Rice film students can use to learn about how film strips are made. We are continuing this project from ENGI 120, so we had a chance to look at their prototype. Let’s just say we have lots left to do. The biggest challenge is that we are unable to test our device using the actual photographic emulsion due to safety and cost concerns, so we have to use a proxy. Another challenge we have is that the film is already perforated and cut before we coat it. Normally, the film must be coated before it is cut or perforated. Finally, achieving an even and consistent coat across the entire film can prove very difficult without the proper machines. There are lots of challenges, but also lots of things to learn.

We are currently doing lots of research to rapidly learn all of the necessary film and mechanical engineering knowledge to design and prototype such a solution.