Hey, how was your week?

My was fantastic, I had a lot of work done and learned a lot of new stuff.

So the week started with me resuming all of my digital circuit project so we, my group and I, could focus on the analog circuit, because we would not have time to finish the digital one.

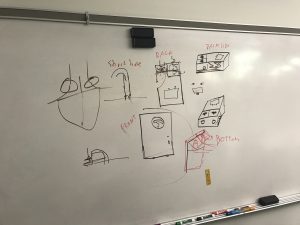

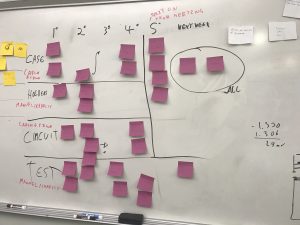

That was during the morning, on the afternoon we began to do a new brainstorming so we could discuss more about case design. We had a lot of ideas on how to position the sensor batteries and how to fix the airflow of the device, we also did a meeting about our plan for the week and all of the tasks that we needed to accomplish, this meeting took the full afternoon, on the end of the day we separated the group in who was gonna do the casing of the device, the testing of the circuit and the making of the battery tester circuit.

Tasks Board

On the next day we started doing our tasks, I picked the battery tester circuit as my task. So I began researching on how to do it and how I could prototype it, after the great help Dr. Woods I was able to understand how the circuit would work and then I moved the sketch to a breadboard so I could test the circuit on real life, it took a little while for the circuit to work but at the end of the day it was almost working but it still had a few glitches.

On Wednesday morning I talked more with Dr. Woods and then I was able to fix the problems with the last circuit, afterwards I began to learn how to use the PCB milling machine, but I had no luck with that. At the afternoon we, all of the SEED interns, went to a baseball game, it was a great way to relax and don’t worry a lot about our projects.

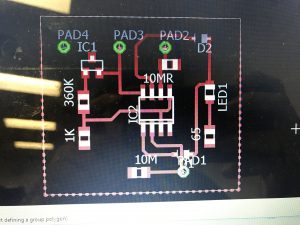

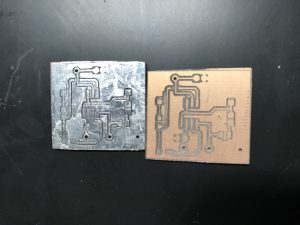

On the next two days of the week I was finally able to make the PCB milling machine to work, so then I started to design it on Eagle, a PCB making software, so I could mill it on the machine, it took a while to make it but at the end it looked good and it was really small, so that’s really great. Afterwards I was able to mill it into a board, but he big problem was that the components for it did not arrived, so I had to start to import the battery tester circuit to the main board, it was a little bit complicated to do that because the main board circuit file was not compatible with the version of Eagle that I was using so I had to change the computer that I was using, afterwords it worked.

So that was my week. Thanks for reading it!!