How did we get around scoring our solutions? By combining them all together of course! Why determine which idea is better if you can just do it all? Our solution was born: Data Fusion. Using a combination of various readings from different sensors (and lines), we can combine the somewhat inaccurate results to produce a much more precise estimate of the syringe’s inner diameter! We can start with current sensors on the Kasupe, add some lines, and then add progressively more and more difficult sensors to improve precision as needed, at the cost of ease of use and money.

Because we spent all of Monday working on distilling down to a single idea, it left us with all of just Tuesday to write, prepare, and present what we have so far. The morning was a mad scramble to compile everything in a nice-to-look-at format while preserving info, and lunch was replaced with rehearsal. It paid off; our presentation went smooth enough, and fantastically considering how long we spent prepping. Poor Arisa started feeling faint near the end, but made the right decision of sitting down rather than pushing through. Better to have to sit down than to pass out!

For Independence Day, we had organized a cookout at Martel for everyone in SEED plus friends. Unfortunately, Houston got hit with quite a bit of rain, which flooded out some people from coming. The clouds cleared in the afternoon, and cookout was still a great success. It was my first time grilling, but the meat turned out fine and everyone enjoyed it. We went up to Fifth and watched the fireworks from there as they launched from across the street.

Back to work! Thursday was arguably the most productive day yet. We figured out our entire measurement methodology for collecting syringe data, called syringe distributors for samples, researched how interpolation works for the sensor data, and made a big list of all the other things that need to be done.

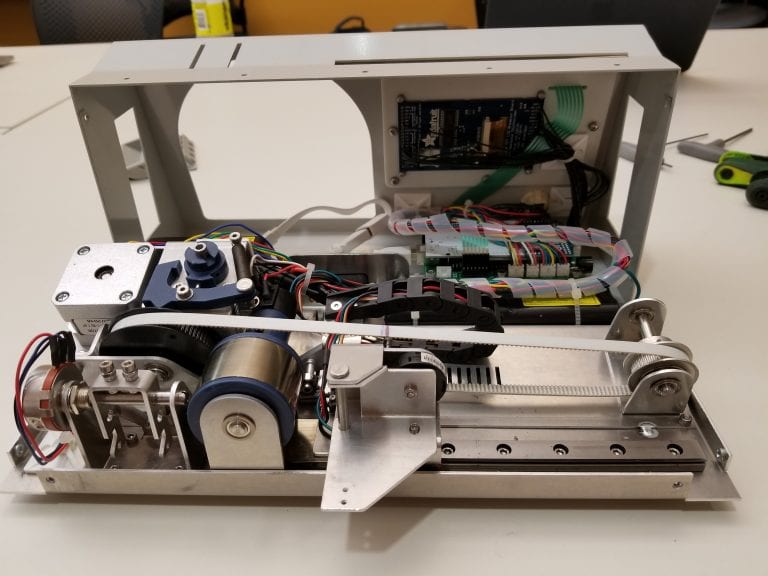

As is tradition with engineers, we got a new machine, so we had to take it apart to see how it worked. I opened the Kasupe up on Friday and found out a lot about what makes it tick. The Arduino is the core of the machine, and controls power flow to everything else. The potentiometer on the lever arm is actually wired in to the chip, but still isn’t being used. Oh, and the Kasupe is broken beyond our ability to repair; the belt controlling the movement of the pusher is physically worn down, no way to fix without replacement. Now we know what we’re working with!

In the afternoon, we paid a visit to Rice Village Medical Supply, a shop about a mile from campus that supplies a couple local hospitals. We met Michael, who became the keystone to our project. He went through his entire syringe catalogue to find the open boxes which matched our specific requests. At less than four dollars a syringe, we managed to order 27 unique syringes without having to buy boxes by the hundred! All the while getting interesting stories and life advice from this guy. Fantastic service, 10/10 would recommend for any medical supply needs.

You are obviously a hardworking and productive team. Harrell and I enjoyed your presentation of your progress Wednesday. I think it was wise of you to work in a conference room to better stay “on task” but am glad your work has paid off and that you have had some fun as well.