It’s been a busy week…

Monday and Tuesday were dedicated almost exclusively towards research. Having little background in fluid mechanics made it difficult for me to know where to start. I decided to begin with an introductory textbook. After identifying the sections that would be most pertinent to our problem, I skimmed over the first couple of chapters to get some of the basics down. I proceeded to read about pressure losses over tube lengths, as well as minor losses that occur due to different components of tubing systems. It was very satisfying to be able to understand the concepts, and to be able to see where they would be applicable to our project. For example, we know that there is likely to be some pressure loss from the pump to the wound-site, as well as some minor losses along the way. This can help us determine how to modulate the power output of our pump so that we can achieve the desired pressure.

On Tuesday we had a meeting with our client liaison (Dr. Abidi), and I researched into some of the other components of our project. Our meeting allowed us to validate some of our assumptions about the waste fluid from the wound (its viscosity, density and whether it was Newtonian), and clarify some of our doubts on the expectations/requirements for the project. The research session focused primarily on pump options, as well as an evaluation of existing solutions (other NPWT products). Later that day we got the chance to present our research to our peers. The response was mostly positive, however, some of them mentioned that we should have also analyzed similar solutions/problems. For example, breast pumps and syringes both operate on the same principle as NPWT so looking into those problems/solutions might help us develop new ideas. We had completely neglected this area of the research process and it was good that we went on to explore it in depth. Our research into breast pumps helped us identify ways in which we could redesign the cap of the device so that no waste fluid was pulled into the pump.

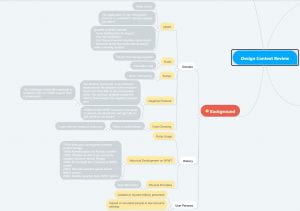

Having shared our research with one another on Wednesday morning, we decided to move onto brainstorming. Rather than brainstorming complete solutions, we decided to go design block by design block. Our project involved too many components, expecting us to come up with complete solutions would have stifled our creativity and prevented us from focusing on all aspects of the solution. As a result, we allocated short 5 minute rapid brainstorming sessions to each design block. Once these were over, we reviewed our ideas and opened the door for “hitchhiking”.

Over the next couple of days, we are hoping to morph these design block ideas into complete design solutions and screen these solutions until we have narrowed down our options to one solution.

You write clearly and concisely about both your individual and team work. Your final statement is especially well-worded and perceptive.

Your team is certainly photogenic. You all look so confident and upbeat.