Welcome to the world of tomorrow! Nothing has changed, except now you can maybe play Kerplunk with tapirs if you scaled our prototype up! The future is now.

Unfortunately, we weren’t able to completely finish the tapir enrichment project, but we at least got to testing a decent prototype and envisioning a final product. If someone has a workshop, a few hours, and sixty bucks to blow, hit me up and I’ll show you what to do.

Monday was the process from paper to product, or at least a prototype. We kicked the day off with a little thing called the Bajaj Challenge, where we simulate motorcycle cart crashes by using a zip line and crafts materials(?). The relationship between the two is tenuous, but basically your (ping pong ball) passengers can’t fall out of your zip line cart upon impact. Anna and I started with a cup, a felt cover, and a couple wood balls before we got the ping pong balls. Once we were given the real passengers, we realized we could leave the wood balls in for weight. Alright seems good, lets test!

Upon impact, we lost a couple passengers. However, one was a wooden “passenger.” Our objective was to protect the ping pong balls. Who cares if the wood ones fly out? That gave me the brilliant idea of absolutely stuffing the cup with rubber bouncy balls. Bouncy balls flew everywhere, but the ping pong balls would survive! It’s real world equivalent would be a clown car crash of sorts where one would intentionally use other clowns to soften the blow for yourself.

Sure enough, and much to Dr. Wettergreen’s vexed doubt of our inspection (all the balls fell out when upturned, but slowly and barely), our design swept both runs of the race. Bouncy balls flew everywhere, but the ping pong balls remained firmly within the vehicle. Great safety rating for two passengers, but certain death for another dozen. Automotive design probably shouldn’t be my thing.

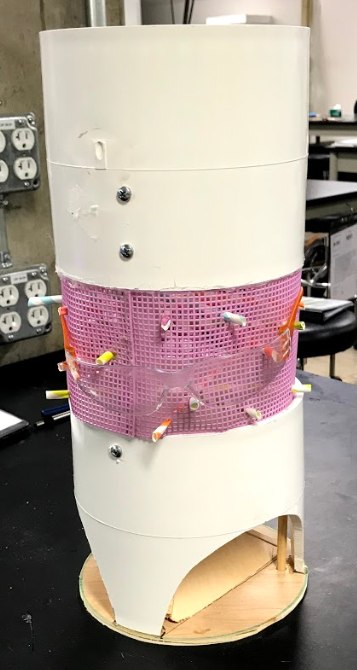

Alright, back to tapirs. The first prototypes looked a little like this:

These were actually pretty good representations for a quick thirty minute job. For the medium fidelity, we basically took the one above and added a slide at the bottom to move food out:

This prototype was as close as we got to finished product. It was made of PVC (though not a single piece), had the mesh (though not fully secured), and the slide (though made of scrap wood), all functional at two-thirds scale. If we had a couple extra days, it wouldn’t have been hard to make a tapir-ready model. Alas, it was time to wrap up this mini-project and move on to the rest of the summer. We made a presentation in a day, gave it the same afternoon, and called it a wrap. Hopefully, another team picks up the project and fulfills the tapir dream.

Wednesday is where the real fun begins. As you can probably tell from the title, I ended up on the Kasupe syringe calibration project, along with Arisa, Eduardo, and Julia. We just so happened to have our client meeting about five hours after getting our project, so we spent the rest of the morning scrambling to prepare. Oh, and also figuring out very important team business, like our name and logo:

S-Caliber! After much deliberation, probably rivaling the time spent on client questions, S-Caliber beat out Epusak and the like in both relevance and punniness. Of course, the next step was to design a logo in Illustrator, not go over more research and questions before the client interview. Time well spent; the logo is great and the client interview went smoothly, despite how overwhelming it was. That was a lot of information at once. On top of it, we had a second meeting the following morning! Erica was on-site in Malawi doing clinical trials with the Kasupe and skyped us to give us a sense of how it’s used in the field. Again very information dense, raising more questions than answers.

The rest of the week was dedicated to figuring out what exactly we’re supposed to do. Through much discussion, we finally settled on these two triangles of use:

The top one is what the engineer would do. They would be able to use a known syringe to check the calibration device, and then use the calibration device to check the Kasupe itself. The bottom one is for how the nurse would interact with the solution. They would give an unknown syringe to the device, and then be able to use the syringe with the Kasupe. With the Wettergreen Approval™, our doubt and confusion of our actual assignment subsided. That’s different than understanding, because I’m still not so sure exactly what to do. Oh well, I’ll figure it out soon enough.

Next week: research!