Hello! I am writing this on a later date than usual, a Sunday, due to a very hectic end to this past week. Ill get to that later, but first will recap from where I left off last Thursday! Last Friday we finished our CAD model for our final prototype, ordered all of the materials necessary to actually build this prototype, and, as always it seems, worked on sewing. We ended that week ready to start seriously building our final prototype.

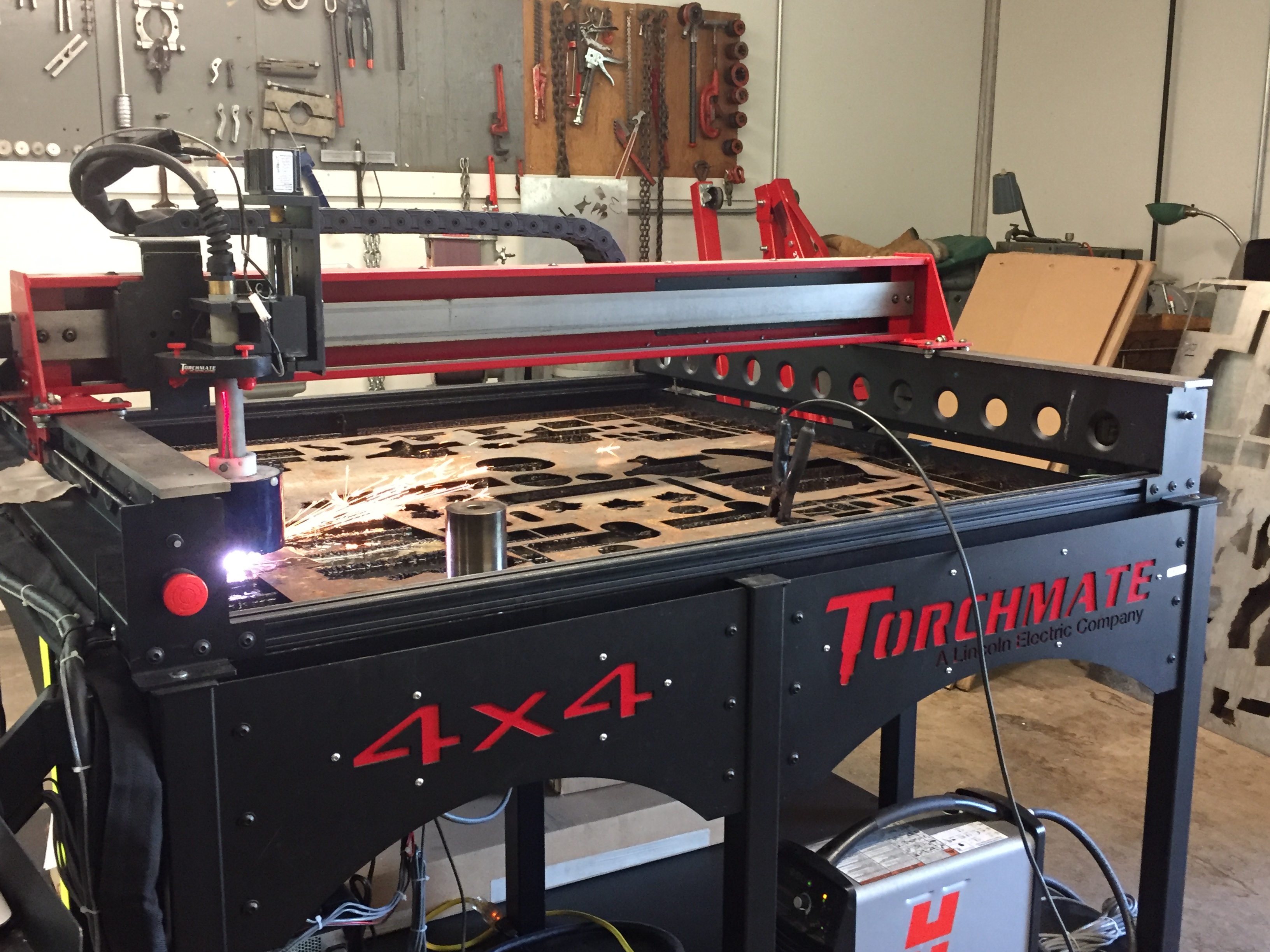

We started off this past week by working on some preliminary features of our final prototype. For a good portion of the week we were kind of at a standstill waiting for our materials to arrive. Despite this setback, we were able to make some progress through practicing tools we planned on using with final materials and low fidelity prototyping some of the features on the final device. We were able to do a lot of this prep work Monday by learning how to plasma cut, 3D printing versions of the handlebars and square to circle inserts.

We were also able to complete all external sewing of the cushions and cut out the plywood pieces to be used to add support to our armrest and base cushions. Going into Tuesday we were still waiting on our square telescoping tubing to arrive, so we continued working on odd jobs. We used our new plasma cutting skills to cut out metal brackets for under the base cushion and for mounting the armrests. Once they were cut, we used the metal bender as needed to create the right shape of brackets. Going into the afternoon, our first shipment of square tubing arriver, so we were lucky enough to begin cutting our final pieces! We weren’t able to get access to Ryon Lab to cut our pieces there, so we used a chop saw in the machine shop, which was both a bit frightening and fun!

Wednesday was the slowest day we had during the week by far. We were finished cutting the tubing we had, so we were waiting on the rest of the tubing to come in, we also did not have access to the welding lab, so there was little we could do with our tubing besides cleaning them. Finally we were also waiting on our foam to arrive to finish our cushions. We did make some technical drawings to help with documentation and for welding reference, and our square to circular connectors were finished by our TA Jeremy. Although we did make some process, I think by the end of the day each of us was frustrated with waiting. We did have a nice break from focusing on our project Wednesday afternoon by going to a Houston Astros game with everyone working at the OEDK this summer!

We started off Thursday still stuck on making progress. We spent the morning planning out the places where welds were needed and generally preparing as much as we could to be ready once we got access to the welding lab. Around 10:30 AM we got some great news: our final tubing had arrived and we would be able to access the welding lab after lunch! This meant were finally able to make some tangible forward process and were able to cut the new tubing and weld all of our base pieces together! While we were at the welding lab with our TA, we got an email from the OEDK saying that our foam had arrived too! Although this day began with frustration and impatience, were were able to have all of our setbacks neutralized, which was both a relief and a necessity. If any of these issues had lasted any longer, I’m not sure that we would’ve been able to finish on time. By the end of the day all of our pieces were welded together, and we were finally making something that resembled our final design, which was very exciting!

Although a lot of progress was made Thursday, a lot of things had to be reevaluated Friday. The frame we completed was too unstable to be acceptable so we spent basically the whole day discussing how we can adjust our prototype and future plans to make a successful prototype. We also talked to our professors about their thoughts, and came up with a compromise between their ideas and our ideas for how to fix our prototype. Going into next week our plan is to remove the two front vertical supports completely, create new armrests with fixed arm grips, and to install our back vertical support on the base from the old team’s prototype. This should make the device stable and portable without sacrificing adjustment. Hopefully at this time next week, our new plan will be implemented successfully and we will be able to present our final device!

Until next week,

Liz Kacpura