Hello! This week has really flown by (because it was only 3 days), so not too much more has happened regarding our project since last week. This past weekend I was lucky enough to get to fly home to the Chicago area to visit my family for the fourth. We were given both Monday and Tuesday (3rd and 4th respectively) off, and it was nice to have a break in the middle of this internship to escape the Houston heat and sleep in y own bed. While I was home I went to an event called Rib fest, where, of course, there are many rib vendors all competing for the title of ‘Best Ribs’. I actually went to this event for the musical guests, on Saturday night we saw A Flock of Seagulls and on Monday, The Wallflowers. Overall it was a very fun trip, and I’m very glad I went, but it was also nice to come back and resettle in to my routine here in Houston. I flew back in the afternoon of the fourth, and most of the interns here got together for a cookout (kinda, we just made burgers indoor though) and to watch the fireworks from Hermann Park, which is across the the street from Rice. It was very fun to show the international interns some American Traditions, and the fireworks show was very exciting!

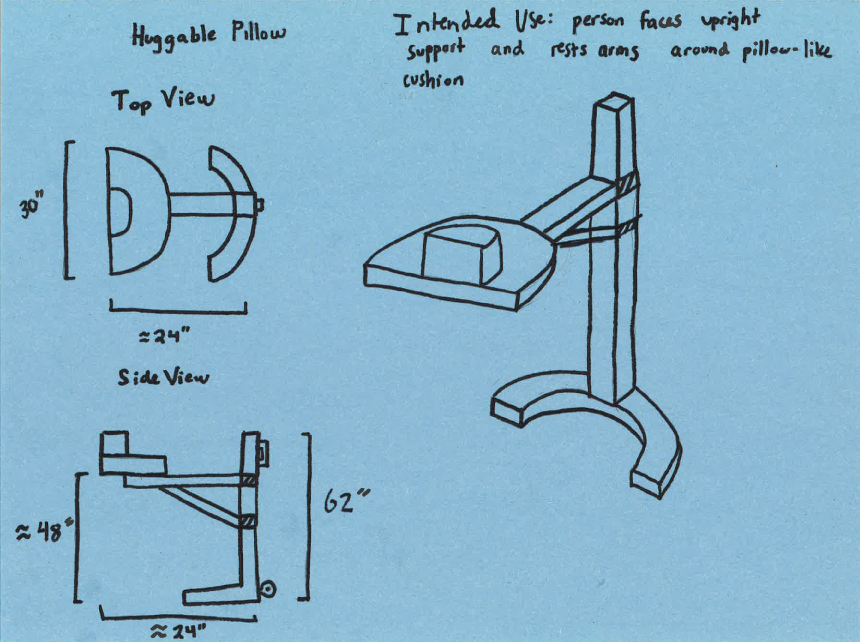

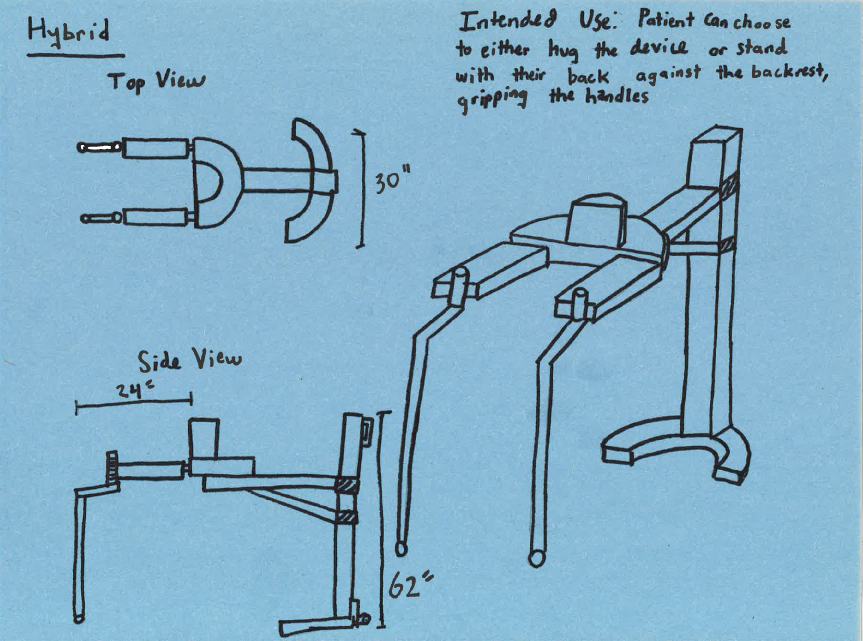

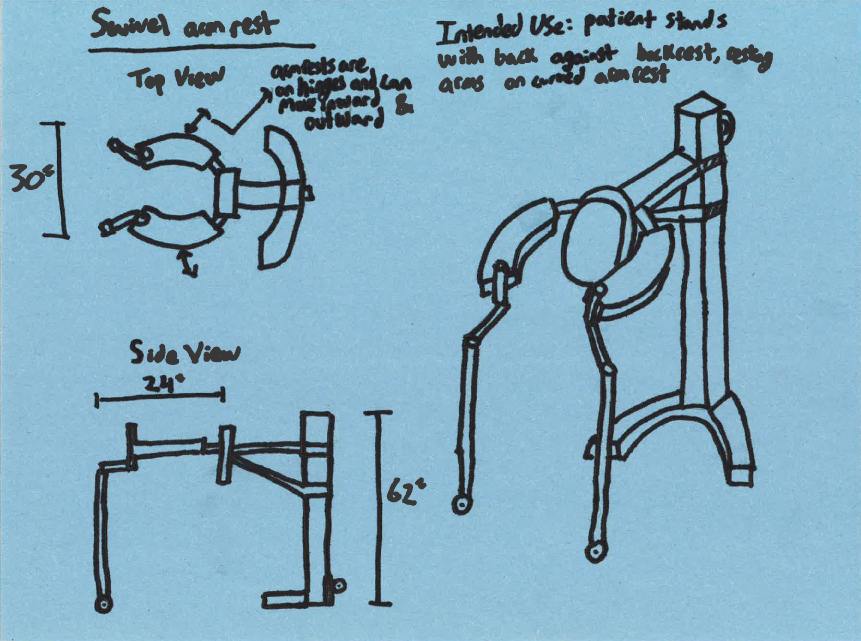

Wednesday morning began with getting back to work after the long weekend. The first thing we started out with was reaching out to our client about his thoughts on our highest scoring solutions from the Pugh scoring matrix. We sent him our top three solutions: The swivel armrest, huggable pillow, and hybrid solution, which are shown below. Each picture also describes how to device is intended to be used.

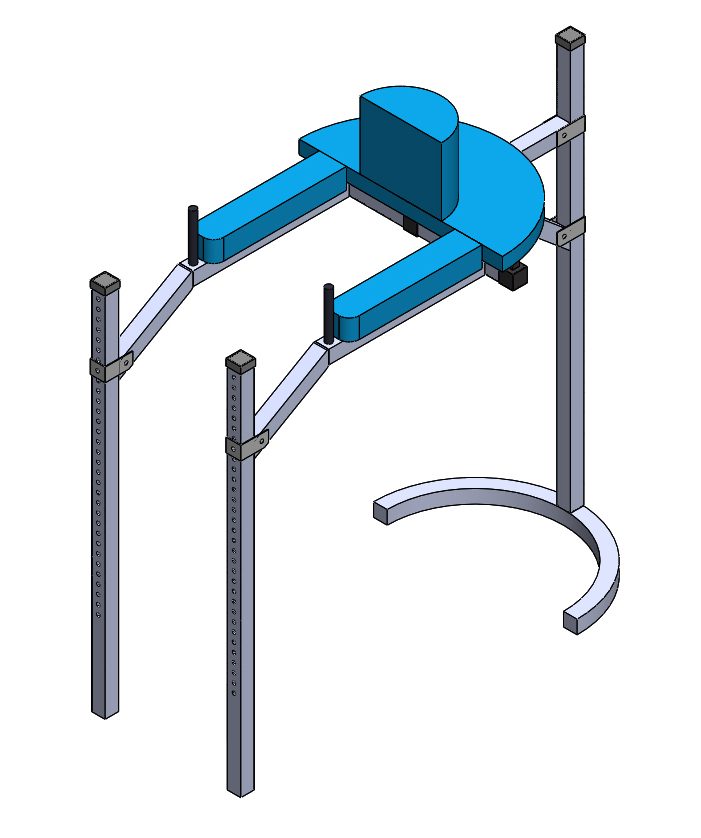

Our client responded that his favorite solution was the hybrid casting stand, which include two different options that the patient can choose between to hold themselves up. The first way is for the patient to rest their back against the vertical cushion and their arms on the arm rests, and the second way is to press their chest against the vertical cushion and wrap their arms around the cushion. Moving forward, we spent the rest of Wednesday broken up, with Alex working on a CAD model of our device, Tori creating our presentation for Thursday and Blessings and I starting some prototyping of some components! We first focused on creating a pull-out pin mechanism, where a pin in extended at rest, and when a grip is pulled, the pin retracts into the body of the device, so that it can move up and down a surface before extending again, locking into the surface. We created this using nuts, bolts, washers and PVC.

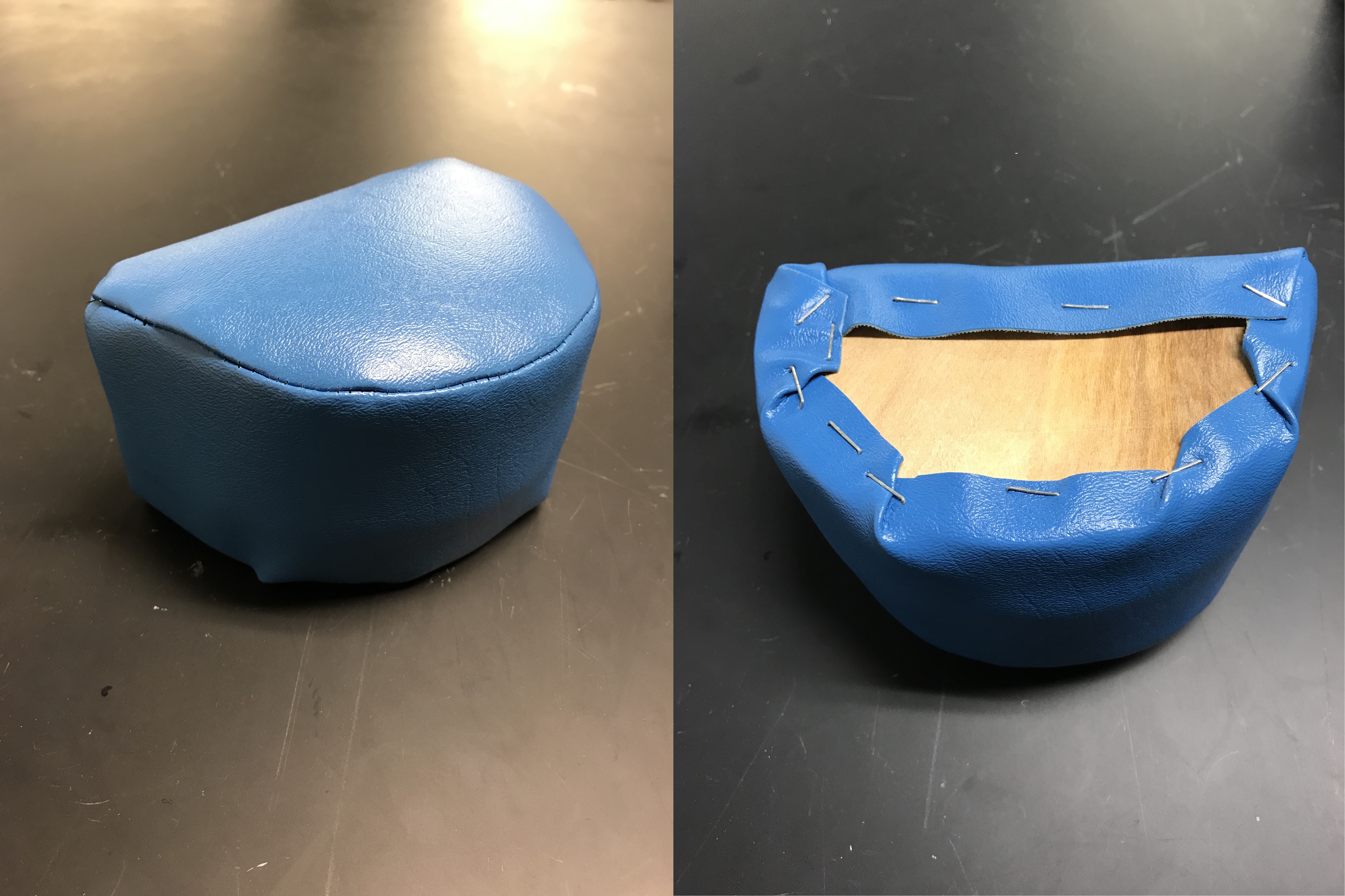

After we finished with this mechanism, we moved out to re-learning how to use a sewing machine (both of us had use them in the past). Our final device will have cushioned surfaces, and we will have to create the cushions ourselves, so we created a small cushion out of vinyl, foam, and a wood base to replicate the cushions we w ill create in the future. After some practice stitches, we were able to successfully create a small cushion!

At the end of Wednesday, we met up as a team, and looked over each others work. Alex’s CAD drawing was absolutely amazing, and the presentation Tori created was very well done. We closed the day by figuring out which slides each person would talk about.

Today (Thursday) was spent practicing for our Mid-Summer Presentation, and right after lunch, actually presenting to the other interns and our mentors. Everything went very smoothly, and it was very interesting to hear about the progress and details on each teams projects! After all the presentations were completed, we spent some time researching wheels and materials and discussing components of our final solution, and will continue on into tomorrow!

Until next week,

Liz Kacpura

Thank you for the update yesterday–so glad your team is in the shop with hands-on learning.