Week 4 at the OEDK! It’s been a short week with time taken for the Midsummer Presentation, and the Fourth of July on Wednesday. Even so, we’ve moved forward in the engineering design process from morphing all the way to prototyping.

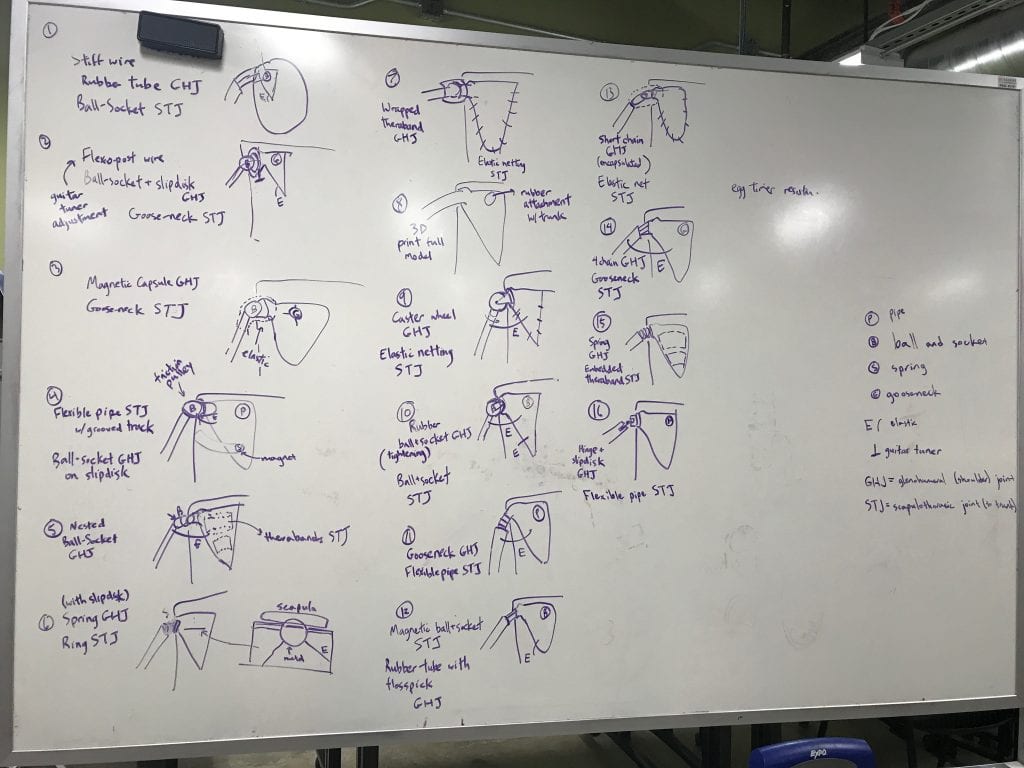

On Friday we morphed solutions from our whiteboard covered in sticky notes. We chose one idea from each category- glenohumeral joint (GHJ), resistance method, and scapulothoracic joint (STJ)- and combined them to make full solutions for the shoulder mechanism. We focused on these rather than choosing scapula or trunk materials right now, because it is the mechanism that we needed to screen and score as a design solution. The morphing went smoothly now that we’ve put in the time to talk through almost all the individual elements on their own. We created 16 full mechanism solutions and drew them out on the board to make sure everyone could refer back to the same idea.

Monday was a power day, in which we went through all of Pugh Screening and Scoring! These can take notoriously long, but once we had a solid idea of how our solutions could work we could compare them in a straightforward manner for screening, deciding which would best meet our design criteria. We took out the criteria of demonstrating exercises and contractors because all our solutions would fulfill those well in theory. We instead focused on ease of understanding, durability, and cost, and we added feasibility as a consideration.

Pugh scoring got difficult when we had to come up with a way to measure “Easy to Understand” and put it on a scale of one to five. During screening we had gone by the idea of “What would look or feel disturbing?” A ball and socket? Good, looks natural and moves the right way. A spring glenohumeral joint? Ugh, no, I don’t want my baby’s arm to bounce around or oscillate! We were going for something natural and intuitive, so it came down to this:

“Quantify what it means to be human.” -Grant

Finally we settled on a list of four binary characteristics, such as natural motion and few exposed mechanics. We started with a default of one point and added one for each positive characteristic a solution had. Voila! Minimum 1, maximum 5, and we have our scale!

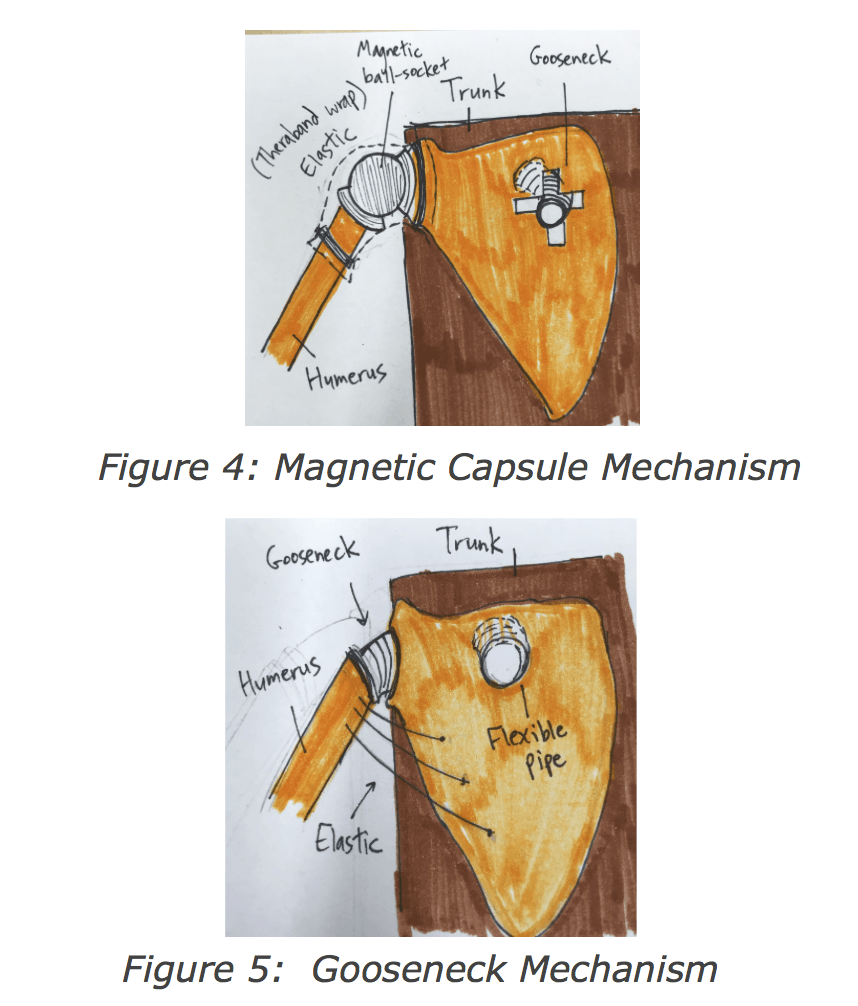

We used a similar system to define a scale for feasibility and durability, and soon had our Pugh Scoring all set up. And the winner is…… well, it’s complicated, actually. We have two solutions that had similarly high scores, so we’re going to move forward with both for the time being. The first is a magnetic ball and socket GHJ with a gooseneck connecting the scapula to the trunk, and the second is a gooseneck shoulder joint with a flexible pipe and slip disk connection to the trunk. The materials are cheap so we just ordered for both, and we anticipate having to go through multiple iterations as we see which materials/strategies may or may not work.

Starting Monday and into Tuesday, we created the powerpoint for our presentation. There was some confusion about how many of us would present each time, but we straightened it out to having all four of us participate this time, and for the final one it is TBD. We practiced our presentation very effectively I found, first going through each slide as a group and discussing what information to cover. Then when we did the full run through each presenting one quarter, it went fairly smoothly.

Tuesday afternoon we gave our presentations (mostly to the other teams as audience; I am looking forward to more viewers for our final presentation). Team Can’t Brachius went first and we did well, I think. I’m finding that when I am up there I actually prefer presenting to standing there as others talk, trying not to look awkward. It certainly doesn’t help to have a camera panning in your direction half the time!

Wednesday was the Fourth of July, and we had a SEED cookout that barely escaped being rained out. After quite the adventure getting the charcoal grill going, we had a great meal and evening. We even got to see the fireworks in Hermann Park from the Martel fifth floor.

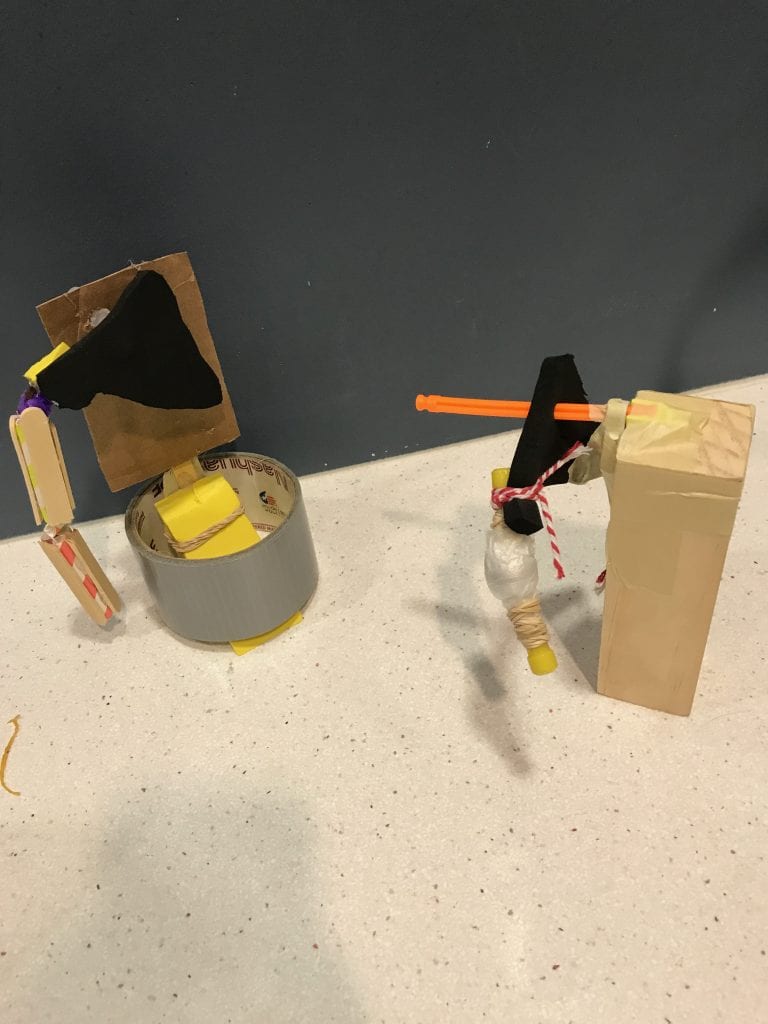

We’ve started low fidelity prototyping, making one model for each shoulder mechanism. These aren’t the best materials, so we need to see how the real ones may fare. We ordered magnets and a section of gooseneck metal tubing, as well as flexible Pex piping to attach the scapula to the trunk.

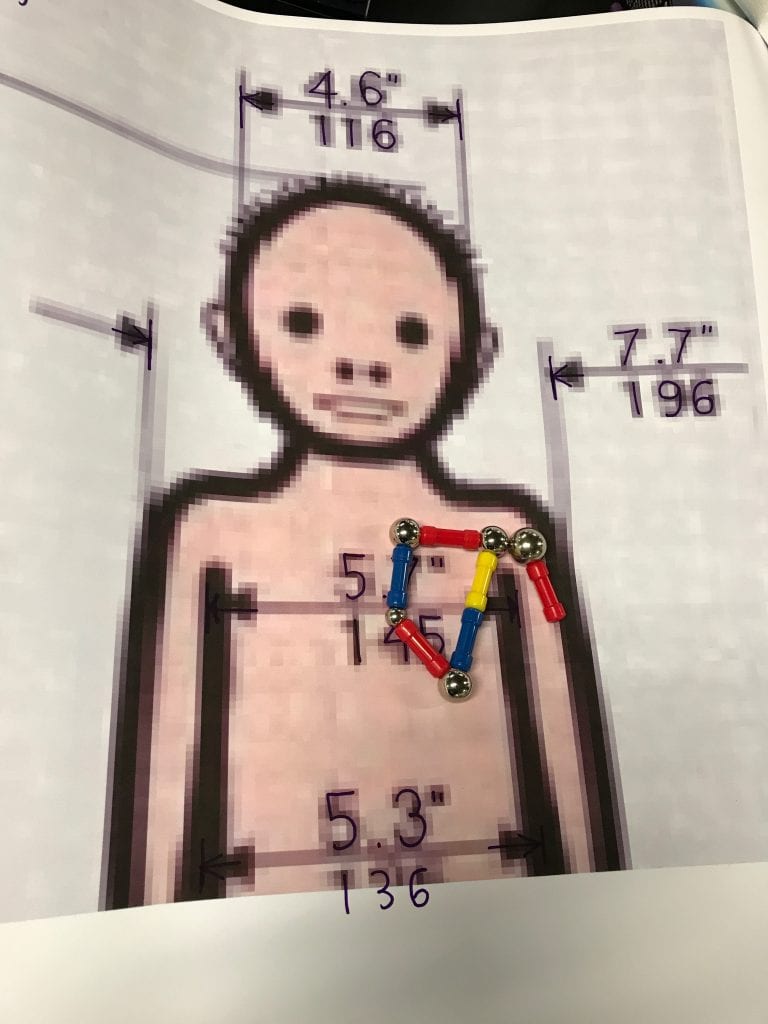

We checked the scale of a 6-8 month old baby, in the middle of our range of 0-12 month olds we want to represent. We printed out a very creepy blurred diagram of the infant at full scale, and researched infant scapula size. The result? An infant’s scapula is 5 cm wide and 7 cm long! If we are making this model to scale, we’re going to have a lot of work ahead of us figuring out how to join all the model’s tiny bones and components. Wish us luck!