Team Gotta Cast ‘em All is back again this week continuing to develop a casting stand able to support a patient while a doctor forms a cast for a prosthetic limb.

This week consisted of research, defining design criteria, brainstorming, and selection of a final solution. But first, I’ll recap what happened last week since my last blog. On Friday, Gotta Cast ‘em All navigated through the Houston public transportation system with Dr. Wettergreen to take a visit to Hanger Clinic, our client for the casting stand device. At the Hanger Clinic, we met with Andre Martinez, who described our motivation for why we are trying to solve this problem, answered our questions to clarify the problem statement, showed us around the rooms where our device would be used, and gave us a brief overview of the process of creating a prosthetic limb. This visit allowed me to better understand why a new casting stand design is needed. I am really excited to be working on this project to help Mr. Martinez and the other prosthetists at Hanger Clinic.

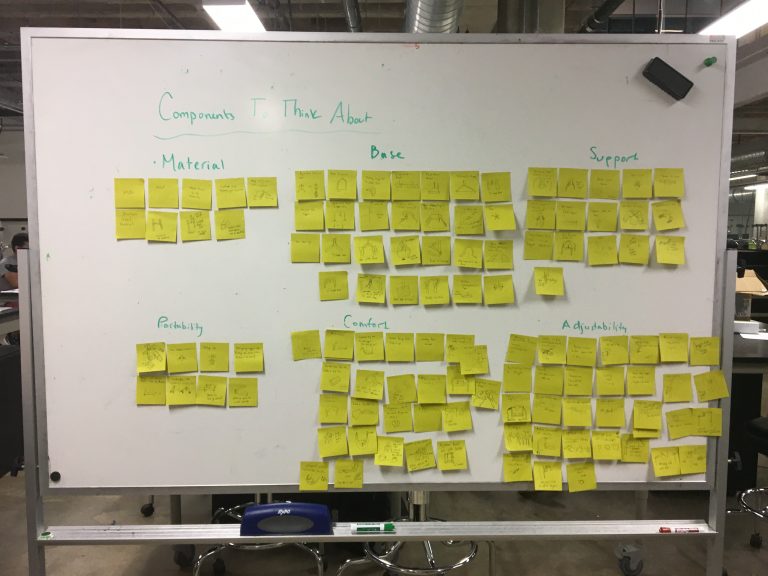

Now back to this week. We researched further into the problem, any existing or similar solutions, various relevant mechanisms, patents, and other relevant information. After conducting research and meeting with our client the previous week, we were able to create design criteria to determine necessary constraints and objectives for our device and prioritize these criteria through a pairwise comparison chart. Our first brainstorming session involved coming up with component ideas for our design blocks. We brainstormed many component ideas during this session, and were able to come up with many different full solutions after using a Morph chart.

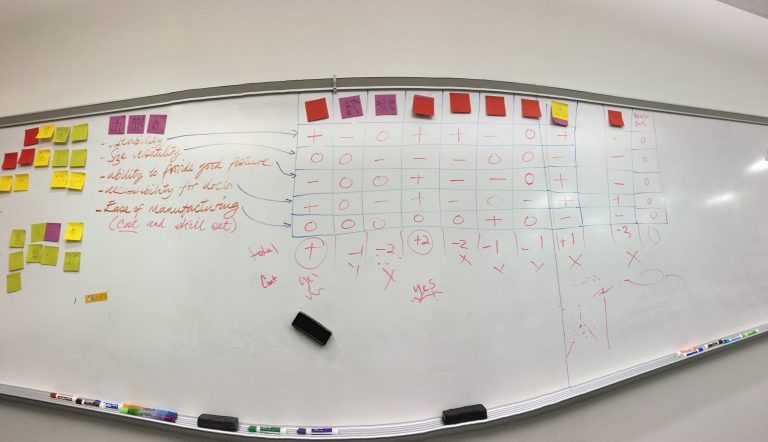

However, when screening the full solutions using a Pugh screening matrix, we ran into issues comparing the solutions. Dr. Wettergreen observed how all our solutions are roughly the same concept, and that our team was design fixated on the current prototype built by the previous casting stand team. This meant that our brainstorm session failed.

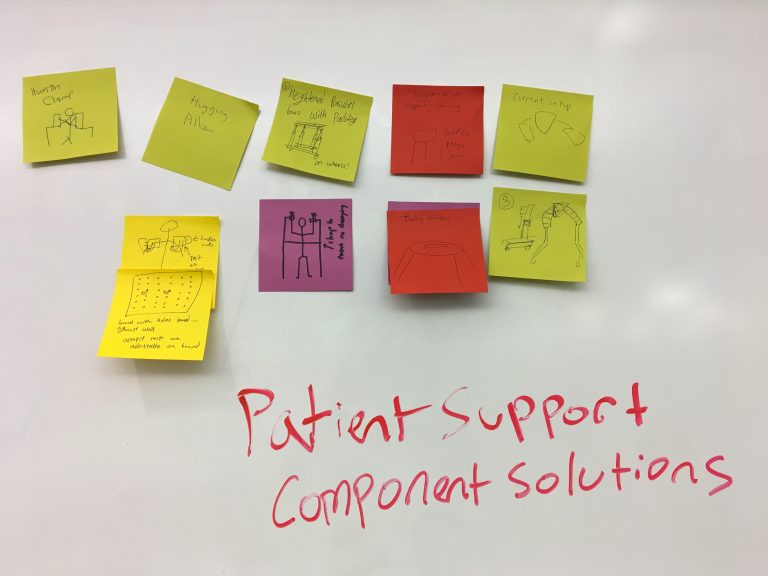

We realized that our ideas did not expand past what has currently been built, and that there may be better methods to keep a patient standing vertically and comfortably. Therefore, we had to conduct a second brainstorm session with more open minds. During this session, we crafted patient support methods that were not a replication or improved version of the current prototype. This allowed us to be more creative and develop a diverse range of solutions. We talked through the solutions we created during our brainstorming session and used a Pugh screening matrix to narrow our 22 patient support solutions into 9 solutions.

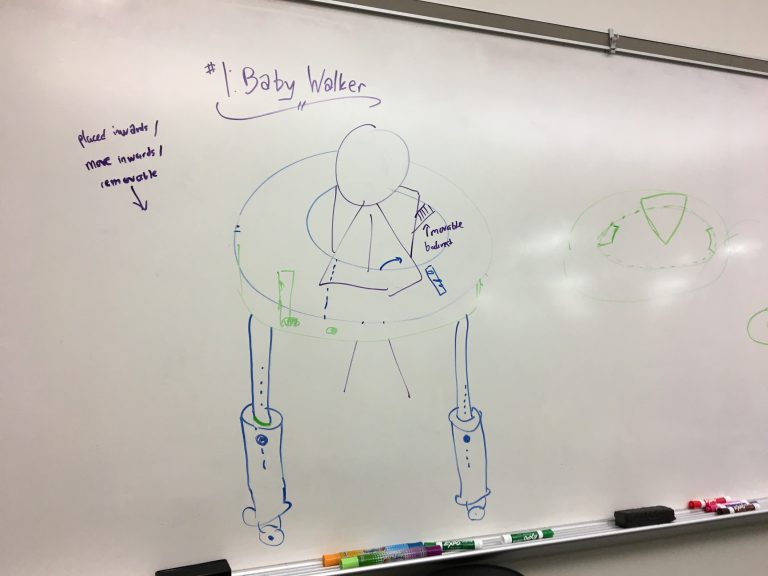

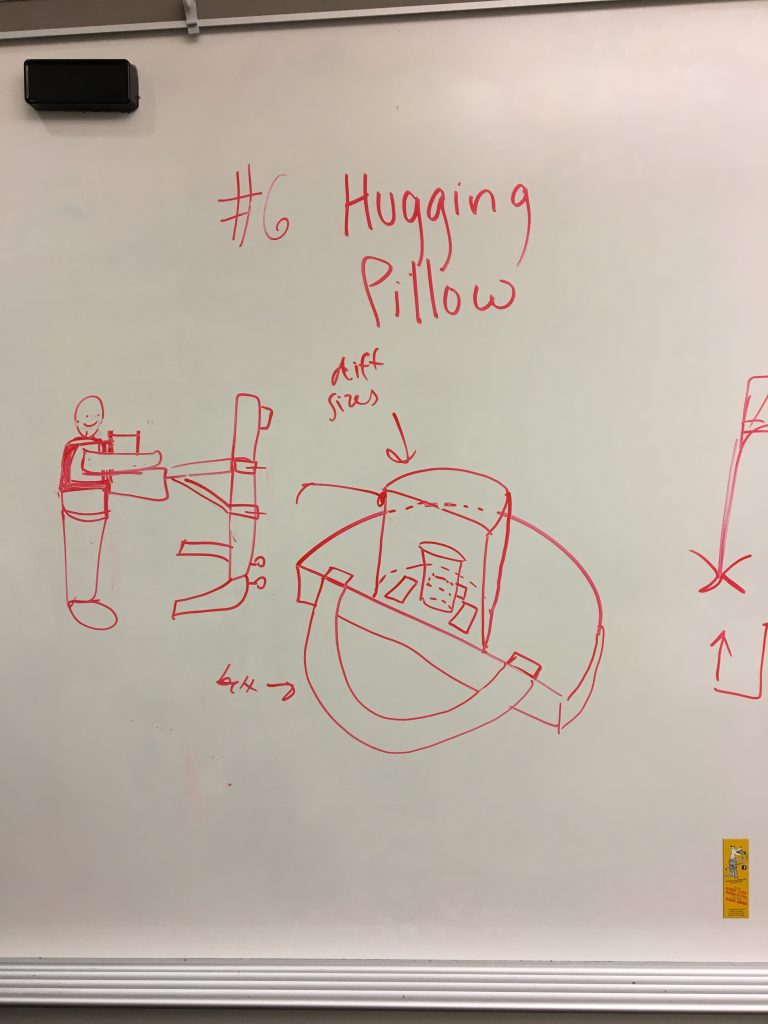

The next day, we took these 9 solutions and drew detailed drawings of the designs in order to create full design solutions. This allow us to flush out how components in each device would interact and consider the feasibility of the design.

A few of our detailed full solution drawings:

Now we were able to create a Pugh scoring matrix to select our final design solution from the 9 solutions remaining after the Pugh screening process. Though, we needed to quantify our design criteria in order to score each solution. Our team is currently working on this step. Quantifying design criteria into something we are able to measure now without a prototype built is challenging. Today, we had difficultly determining how to quantify patient comfort while standing and doctor accessibility to the patient’s limb. Therefore, in order to move forward, we are using the current prototype to check the different postures a person can be in with our design solutions. Once we survey the various postures and consider leg obstruction with the current prototype, we will be able to better rank and quantify the last two design criteria for our Pugh scoring matrix.

Also, Jeremy presented a SolidWorks and 3D printing workshop on Tuesday. Now, everyone is using the 3D printers to print things they have made and random stuff found on thingiverse.com. Here are some notable prints from this week.