My adventures in SEED continues for a second week. This week was very busy with working on a Bajaj challenge, prototyping for a zoo enrichment device, getting our project assignments, and participating in a needs finding workshop.

Bajaj

A challenge activity presented to us this week was to prototype a Bajaj to safely carry its passengers (ping pong balls) down fishing wire from the ground floor to the basement of the OEDK, where it would crash into cardboard. Given only 30 minutes, Bruno and I constructed a fine looking low fidelity model of a Bajaj. Surely we would win the challenge, because our design was obviously very innovative and high quality. Unfortunately, when it came to testing, our Bajaj proved otherwise. In the first round, plastic on the paper clip carrying the Bajaj failed to allow the vehicle to slide down the wire. In our second attempt, we used a larger, metal paper clip. Our Bajaj is ready to win now, right? Due to the circumstances at the time (including Jeremy, our TA, cheating), our Bajaj glided down gracefully but crashed at bottom in a way to release one of the passengers. Despite this failure, the challenge was still exciting.

Team Lion

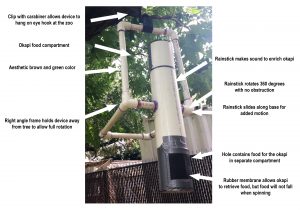

Last week, we were tasked with creating an enrichment device for okapi at the Houston zoo. After conducting research, brainstorming, and choosing a final solution design the previous week, this week involved prototyping our design solution. My team developed a spinning rain stick feeder that would engage the okapis through sound, motion, and food. We went from low fidelity prototypes to higher fidelity prototypes made out of PVC, wood, rubber, and glue. The device was painted brown and green so it would better blend into the exhibit’s environment. In the exhibit, the device will hook onto eyebolts attached to trees by means of a carabiner.

To Cast Them All is My Real Test

Starting Wednesday, we were all introduced to the projects that we will be worked on for the rest of the summer. The four projects included a casting stand, diabetic foot ulcer checker, a wheelchair transfer system, and an oxygen calibrator. Three other students and I were assigned to the casting stand project, and I am excited to be working on this project for the summer.

The problem surrounding this project is that patients missing a leg require casts to create a prosthetic leg for them. These patients must stand still for greater than 10 minutes in order for doctors to create a cast for the prosthetic leg. Often, these patients are weak, and it is difficult for them to stand still this long. Current solutions used in hospitals consist of parallel bars and hanging straps.

This project began as an ENGI 120 project in fall 2016. The other team developed a prototype from exercise equipment, steel bars, and foam padding. Even though their prototype technically works in supporting a person to stand on one leg, the device is neither comfortable nor stable, and its adjustability could use improvement.

My team’s next steps for working on this project is to meet with our client this afternoon and to continue conducting research on materials, mechanisms and methods for components of the device, and similar solutions related our problem.

Needs finding workshop

On Thursday, we participated in a needs finding workshop given by a Rice bioengineering professor. This workshop was both very informative and interactive. We were asked to consider issues and problems facing our university. After also considering the problems people with a disability face, we then participated in activities to imitate the challenges that people who are in a wheelchair, blind, or have arthrogryposis face. Not only were the activities entertaining, but they also allowed us to have a better perspective of these groups of people.