The end of medium is near! Towards the beginning of SEED Caz assured me that prototyping would go much faster than expected and he is right. We have iterated a solid few prototypes since  seeing James last Thursday! Friday we kicked off by trying to replace the flexible hosing with a spring. This proved to be an interesting challenge because metal springs are far more difficult to attach than rubber. We settled on making this strange metal cross thing inside our slip disk (seen to the left) and seeing how the spring held up. Unfortunately we found the spring was far too loose but we learned a lot! We also had a chance to try and decide on which spring to use. The OEDK has a large selection of steel springs so we raided the supply and tested how each of them held up various weights! In essence, Friday was the beginning of the spring era in our prototypes!

seeing James last Thursday! Friday we kicked off by trying to replace the flexible hosing with a spring. This proved to be an interesting challenge because metal springs are far more difficult to attach than rubber. We settled on making this strange metal cross thing inside our slip disk (seen to the left) and seeing how the spring held up. Unfortunately we found the spring was far too loose but we learned a lot! We also had a chance to try and decide on which spring to use. The OEDK has a large selection of steel springs so we raided the supply and tested how each of them held up various weights! In essence, Friday was the beginning of the spring era in our prototypes!

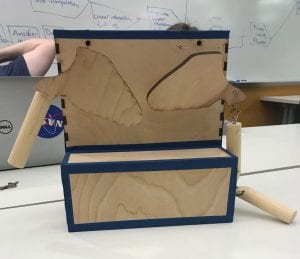

Monday kept to the theme! We attempted to revise our spring attachment method because the spring cross was just not looking promising. Instead, we decided to glue the last few coils of a spring around a dowel and see how it went. This turned out to be the breakthrough we were looking for and we managed to crank out an entire medium fidelity prototype. We experimented with using glue instead of screws and discovered that with about an hour wood glue does a more than adequate job of holding the scapula pieces together. We also had an exciting material arrival Tuesday. We decided to try and use swivel clasps to replace the elastic in the old prototype!

to glue the last few coils of a spring around a dowel and see how it went. This turned out to be the breakthrough we were looking for and we managed to crank out an entire medium fidelity prototype. We experimented with using glue instead of screws and discovered that with about an hour wood glue does a more than adequate job of holding the scapula pieces together. We also had an exciting material arrival Tuesday. We decided to try and use swivel clasps to replace the elastic in the old prototype!

Wednesdays morning meeting was a couple steps back. We had created many functional new aspects but they looked rough. We spent most of Wednesday trying to trouble shoot our slipdisk and hide some of the rougher looking components. We attempted to use heat-shrink tubing to hide the springs but unfortunately the tubing makes the springs too inflexible. We also tried to find a replacement for the  swivel claps but that proved to be elusive. James’ enthusiasm has been keeping our spirits a little higher than last week. I love his appreciation for our work but has slightly lower standards than our professors and TA’s. I think they have been making a concerted effort to push us to be the best we can be. Wednesday was not an immense amount of progress but we managed to eliminate several failed ideas. To end the day we experimented with stains and laser etching the Texas Children’s Hospital logo into the back of the box. Apparently they have some fairly stringent rules with how and where their logo can be displayed… Fortunately the staining and etching has been coming out nicely.

swivel claps but that proved to be elusive. James’ enthusiasm has been keeping our spirits a little higher than last week. I love his appreciation for our work but has slightly lower standards than our professors and TA’s. I think they have been making a concerted effort to push us to be the best we can be. Wednesday was not an immense amount of progress but we managed to eliminate several failed ideas. To end the day we experimented with stains and laser etching the Texas Children’s Hospital logo into the back of the box. Apparently they have some fairly stringent rules with how and where their logo can be displayed… Fortunately the staining and etching has been coming out nicely.

Today, we created an internal ring to keep tings from getting between the scapula blades. Fortunately we the laser cutter is a truly beautiful and precise machine! The result was insanely satisfying! We spent a portion of time trying to balance our shoulder blades so they hang more naturally however we discovered the center of mass is hanging off the side of the scapula thanks to the arms so there is not much we can do on that front. The final improvement of the day was finding out how to use the heat-shrink tubing to finalize the weaker looking joint. The results were pretty but I accidentally melted one of our 3D printed brackets so that method will need some improvement! We will be pushing over the next few days in order to finish by next Tuesday. At this point I am greatly looking forward to the presentations and giving James a product he can use happily!

Sorry!! this week I couldn’t get all my pictures inside of the text so here are the rest I wanted to include!